Process Improvement

What Can Process Improvement Do for Your Business?

A standard definition of process improvement is “the proactive task of identifying, analysing and advancing upon existing business workflow within an organisation to optimise company operations and meet customer demand or quality measurements.”

Often, we run into problems while attempting to improve one step or several small steps within a process because we aren’t looking at the upstream or downstream effects of those process changes. Business process improvement (BPI) is key to staying competitive in ever-changing markets, but it is also vital for employee engagement and morale.

All in the Process Improvement Family

There are several different methodologies that companies use to improve their processes. Some prefer Six Sigma, while others prefer Lean, rapid improvements, total quality management (TQM) or theory of constraints — or any combination of these (such as Lean Six Sigma).

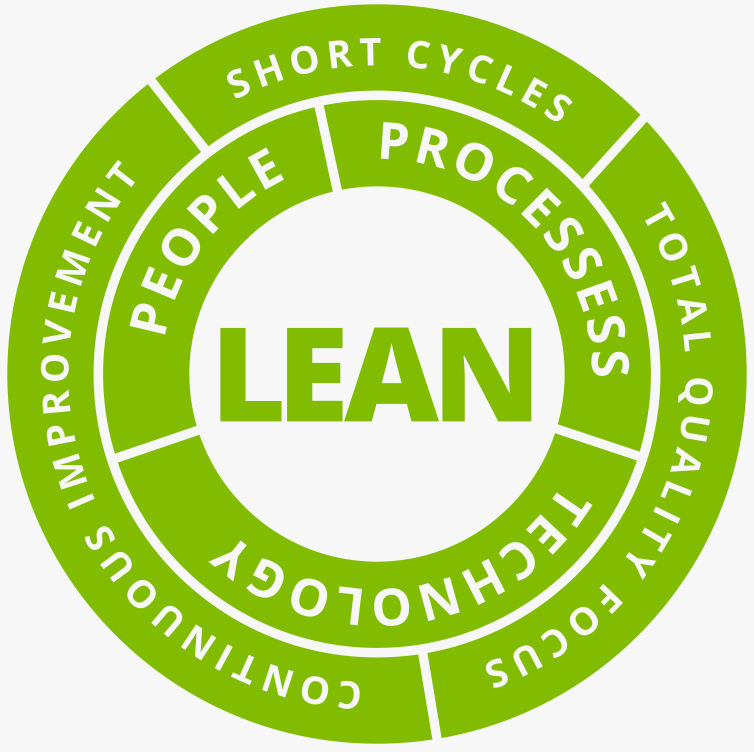

Lean

Lean is a customer-centric methodology used to continuously improve processes through the elimination of waste. For example, if you’re improving your processes via a purely Lean lens, you will look to rapidly — yet methodically — remove the non-value-added steps within your process.

Lean is genuinely a methodology for the people by the people. It makes you look at each step within the process and ask yourself or the team, “Is this step in the process adding customer value?” If the answer is “no,” it is incumbent upon the team to look for ways to eliminate that step or mitigate the time it takes to perform that step in the process.

Six Sigma

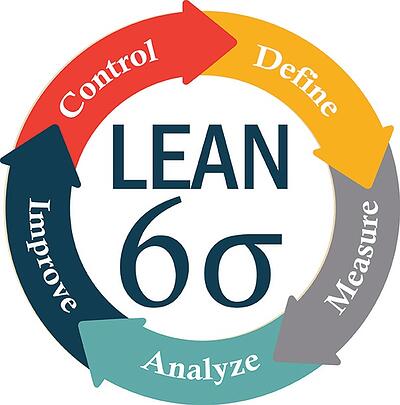

You can — and should — take several steps to improve a process. When we discuss the many different methodologies within the process improvement family, you need to understand a few key concepts:

- Define the opportunity or problem.

- Measure the impact of that which you are trying to resolve.

- Analyze the situation or issue.

- Improve the process.

- Control the new process to sustain your results.

Combined, these steps refer to DMAIC within the Six Sigma methodology. DMAIC drives you to complete these steps for the best possible outcome when looking to improve a process. The ultimate goal of Six Sigma is to reduce variability within your process.

A common mistake that we often make during this process is skipping the first three steps and going right into an improvement mindset. It’s so easy to catch yourself saying, “I know exactly what’s wrong! If we do this, then we will fix our problem!” While such a thought draws to a quick solution that might make sense, it will not actually resolve the problem or improve the process for the long term. Six Sigma advocates ensure your company reviews a solid data set during any project’s analysis phase.

There are many critical aspects of improving a process. Still, companies often overlook determining how the process change might affect other departments — either upstream or downstream from your process change. This includes communicating the process change to those upstream and downstream partners within your business.

Lean Six Sigma

Organisations often combine Lean and Six Sigma to optimise capacity, reduce cycle time, and eliminate variability in all processes.

Merely changing one step in a process can negatively impact a customer experience or employee experience if it’s not effectively analyzed and communicated. Going back to the restaurant take-out example, if they simply improved one step of the process, they would have only gone so far. If they had only made one improvement, they likely would not have positively impacted the customer experience.

For instance, just adding the ability for a customer to place an order on a website would not have solved the delays and confusion during the pickup process. Instead, they looked at every aspect of the process, from the ordering experience and the preparation to the picking up of an order.

By looking at the entire process, considering each possible hand-off and touchpoint, and seeking improvement, they effectively went from a highly dissatisfied experience to delighting customers with fast, friendly delivery of their meals and minimal wait times.

Other Methods

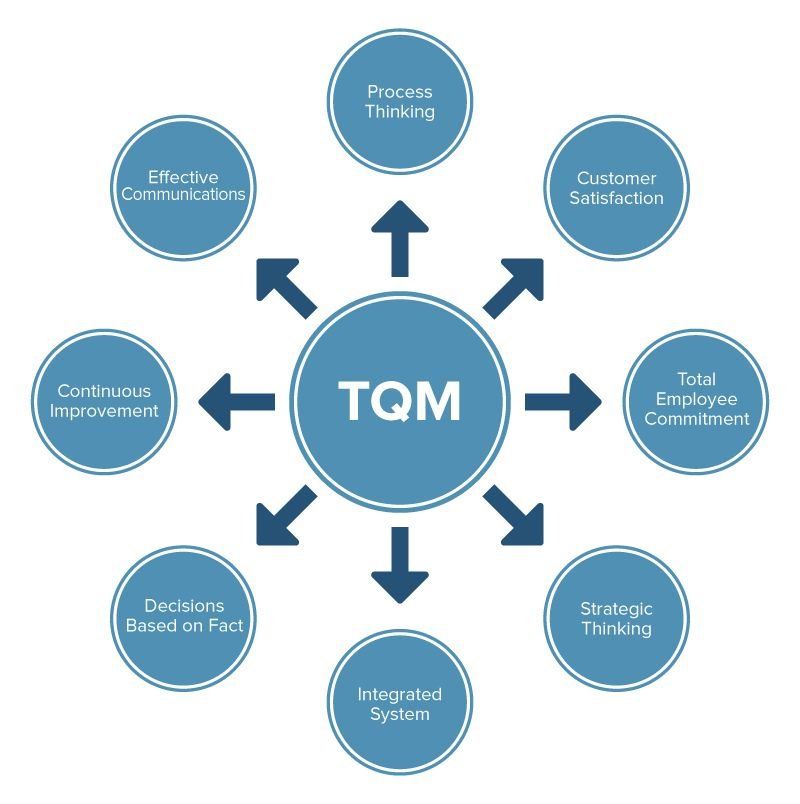

As I mentioned earlier, there are other methodologies beyond DMAIC that you can use, such as rapid improvement. And some organizations prefer a TQM approach or Theory of Constraints.

Rapid Improvement: Rapid Improvement is a streamlined activity, such as Just-Do-It, designed to be action-oriented and address readily apparent issues. This methodology is a simple tactical focus to fix known problems with obvious quick resolutions that are easy to implement and carry minimal risk.

TQM: TQM, or total quality management, highlights the steps, “Plan, Do, Check, Act.” This management system is based on the idea that every team member is dedicated to and maintains high work standards across a company’s operations.

Theory of Constraints: The Theory of Constraints model focuses on finding any process bottlenecks and improving that bottleneck or constraint until it is eliminated altogether.

These methodologies are all effective if you have the correct effort, execution, and adoption throughout your organization.

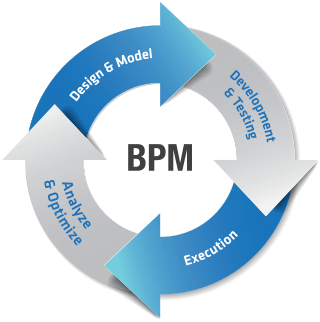

No matter which methodology you choose (or combine!), however, having the right tools can make process improvement that much easier — which brings us to business process management (BPM).

Business Process Improvement Complements BPM

Many companies and organisations have stated that process improvement and BPM complement each other by providing the push for improvement with low effort.

First, you need to know what both BPM and BPMS are:

Business process management “is a disciplined management approach and methodology that provides end-to-end process understanding, visibility and control while ensuring effective communication across an organisation.”

A BPM solution (BPMS) “brings technology into the BPM equation by providing a platform to model, manage, optimize, and rapidly adjust business processes. These technology solutions are toolkits for solving multiple process-related issues through automation, collaboration and visibility.” As an example, a new solution called hyper-automation combines BPMS with robotic process automation (RPA) and artificial intelligence (AI).

Suppose you have already gone down the BPM route. In that case, it will help solve critical challenges for Lean or Six Sigma initiatives that make them even more useful, without having to get executive buy-in or creating a new “program of the day,” so to speak.

BPM is not only technology meant to help organisations achieve their business goals, but it can also bring process improvements to the next level.

An essential part of using a BPM solution is to ensure you are looking to optimise your processes before adding technology into the picture. You must standardise and optimize your processes before automating them; otherwise, “automating a bad process just gets you bad results faster.”

Optimizing processes before implementing BPM also helps you grow your appetite for improvement by influencing your team to adopt a continuous process improvement mindset. Both of these influence each other, too, as a continuous improvement culture can lead to a successful BPM model deployment.

Keeping Process Improvement Continuous

Once you have established the momentum of process improvement, it is the continuous piece that is hard to sustain. We all know the impact of a few successful projects or changes can stir excitement. This could be the beginning of a cultural transformation; once people are part of an improvement opportunity, it can open their minds to look around and improve other parts of the process.

Putting in place a plan to drive continuous improvement is your next hurdle. A common phrase you might hear is, “We already looked at that process. We don’t need to improve it.” That sends shudders down a process improvement practitioner’s spine because the goal is always to improve the process. You must integrate the improvement mindset into your entire organization — not make it dependent on a centralised team to identify your company’s needs. Switching from a centralized to a federated model is critical to achieving a true continuous improvement mindset.

But once your employees feel empowered and comfortable to present ideas and thoughts to eliminate waste and improve your processes, you have well-established a process improvement culture.

Just ask yourself next time you place an order for pick up at your local restaurant: Would you only want one aspect of your experience improved, or would you like to be continuously delighted each and every time you place an order and pick it up?